The toilet wouldn’t flush.

I looked in the tank to see what was wrong. There was a brick inside!

“Honey,” I yelled to my wife, “how did a brick get into our toilet tank?”

“I put it there.”

“Why?”

“To save water. I read in the newspaper that a brick displaces enough water to save a gallon a day. What’s the matter? Did I put it in wrong?”

Muttering about cockamamy ideas, I reached in, grabbed the brick and deposited the dripping thing in the wastebasket. I’d had it with all this ecology stuff. “Don’t use plastic bags. Save this. Save that.”

Last Sunday in our church parlor, I burned my hand on a paper coffee cup because the United Methodist women had done away with Styrofoam cups, which aren’t biodegradable.

Frankly I was ready to biodegrade all those who preached about everything from pesticides and garbage disposal to recycling and the ozone layer.

After all, what can one person do? Save a few watts here, a couple of gallons there, a few plastic cups in the garbage dump? For me it was getting ridiculous. Then I met David Buckley.

David is a lawyer in Vermont, and he’s also a businessman, a most unusual one. He’s a power-plant builder, and that’s what I decided to investigate. For a long time he’d had the idea for a hydroelectric development at a dam site and a small waterfall to generate electricity outside his hometown of Bellows Falls.

So it was that I found myself tooling through the green hills of southern Vermont, slipping onto Route 103, passing Vrest Orton’s country store, turning at the sign that said Brockway Mills and stopping on a bridge over the Williams River.

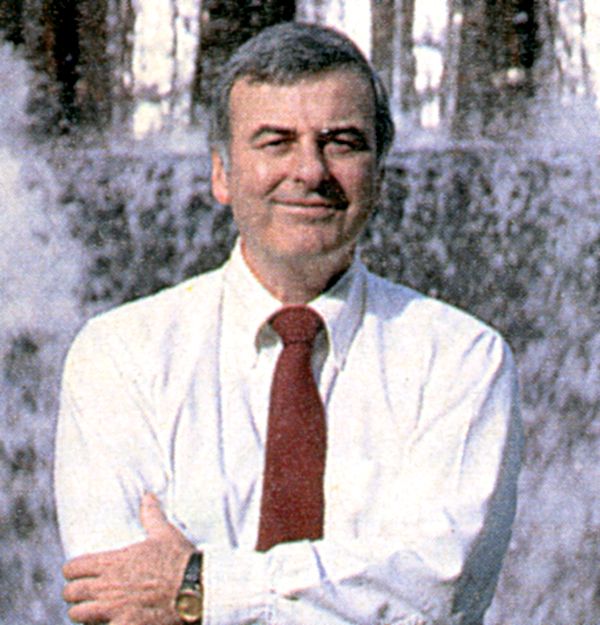

I was met by David Buckley, a friendly, soft-spoken fellow with eyes as clear as the water underneath us.

There behind him was the Brockway Mills dam and, below it, the hydroelectric plant hidden in a concrete structure.

When Buckley told me it generated only enough power to supply 400 homes, I was surprised. But after hearing his story, I gained a new appreciation of what some people will do on behalf of our environment.

“My dad used to take me to this spot as a boy,” David said, looking up at the maple-shaded river. “It was my favorite swimming hole. All the years I was away—in the army, then at Notre Dame and later in law school—I used to think about this spot.

“I always knew I’d come back to Bellows Falls to practice law, and when I did, I wanted my wife and two children to enjoy the same things I had relished as a youngster—fresh clean air, sparkling clear streams and woodlands to hike.

“Then in 1979 when President Carter appealed for alternate energy sources during the oil crisis, and we all waited in line at gas stations, I felt I should answer the call.

“I’d always been fascinated by dams. Every spring we kids used to go over to the big Bellows Falls’ dam on the Connecticut River to watch the ice breaking up. When the huge frozen expanses split and fractured, they produced a thundering roar that echoed off the face of Fall Mountain, frowning over our village.

“Even then I was intrigued by the big power plant, which has been there since 1928, and by the way its water-driven turbines spun massive generators to supply New England with electricity. Such dams had been part of our heritage; our village had depended on waterwheels to grind grain and later run paper mills.

“And I loved the terms used in dam construction, terms that stemmed from early farm language. The sluice sending the water to the mill wheel was a pen-stock, and the movable gate allowing water to enter the sluice was a wicket. If floating debris was caught in the gate, the miller complained of a sticky wicket.

“So I decided to develop a hydroelectric plant using a run-of-the-river diversion dam. It was clear that every kilowatt generated from the river would mean less dependence on petroleum and coal. It would cut down on air pollution and send less carbon dioxide into the atmosphere, reducing the greenhouse effect.”

But to make it work, the project would have to be a profit-making venture. With a friend, Sandy Hadden, and other investors, David formed the Williams River Electric Corporation, and purchased a site on the river to build their plant.

They didn’t know the tremendous obstacles that lay in wait. Endless snarls of government red tape, a souring financial prospect, crippling construction costs.

It began in 1981 when they applied to the Federal Energy Regulatory Commission for a permit. Their first roadblock was heartbreaking.

To house the new turbine and generator, Buckley had planned a picturesque structure patterned after the original water mill that operated here almost 200 years ago. On the same site, it would least affect the natural surroundings.

No, said the authorities. The new plant had to be hidden deep in the gorge under a concrete housing. This meant blasting away the natural rock.

“I wondered if it was worth going on,” said David. “But my partner argued we couldn’t let that stop us. ‘It’s crazy not to use this power,’ Sandy said. ‘It’s freely available and does no harm to the environment.'”

So the two men struggled on, running the gauntlet of over two dozen federal, state and local agencies, from the historic preservation division to the Fish and Wildlife Agency, explaining well-worn blueprints and telling the same story over and over again.

This is when they began referring half-humorously to their little company by its initials, WREC.

Finally, after 14 months and spending more than $22,000 in engineering studies and projections, they got the permit.

“What sustained you all that time?” I asked, thinking most people would have thrown in the towel long ago.

“My mother’s prayers,” said David, “and the hope that what we did might encourage somebody else to use our natural resources in an economically intelligent way.”

But in early 1983, after construction had started, oil began flowing from the Middle East again. With the heat off the energy crisis, electricity rates for small producers dropped.

“It was a major blow to expected earnings,” said David. “Interest on our debt was climbing and we had investors to think about. Yet we couldn’t let our dream die. I thought of those early millwrights who built the original water mill here, using oxen and primitive hoists. That took determination. I figured our mill would require the same.”

As construction started on the new concrete dam across the Williams River, the engineers made a surprising find. Excavations showed the new dam followed the same keyway line of the dam that had stood here two centuries ago.

“Seemed a sign from heaven we were on the fight track,” said David.

However, construction costs soared far above original estimates. When a company from Beijing, China, offered the best price on a turbine and generator, David ordered it. What he got was a Chinese puzzle.

“The generator and turbine were not assembled as promised,” said David. “Special tools had to be ordered from mainland China. Though Chinese technicians came over to install it, they couldn’t stay long enough to finish the job.

“On top of that, the translated instructions that came with the equipment were almost incomprehensible.”

David gave a wry laugh. “To make matters worse, the electronic controls had to be replaced with American-made equipment. There went most of our savings. However, by now Sandy and I felt our resolve was stronger than the calamities that challenged it.”

Finally, in January 1987, the Williams River Electric Corporation was on-line.

David Buckley ushered me down concrete steps into the cool powerhouse. I gazed up at the green generator towering over us. Over at the control cabinets, an engineer began the start-up countdown.

A green light flashed, a master switch thunked, the wicket gate opened and Williams River water roared down the penstock to spin the stainless steel turbine blades. The generator thrummed, needles flickered on gauges and a steady hum filled the powerhouse.

I stepped outside, climbed the steps and stood reflecting on the bank of the Williams in the bright afternoon sunlight.

Because of David Buckley, Sandy Hadden and others who shared their dream, the Williams River Electric Corporation was feeding 850 kilowatts of cleanly produced electricity into the Vermont power grid.

True, it was only enough to run refrigerators, washing machines, lights and toasters in some 400 homes. And though it was making a small profit, it wasn’t going to make anyone rich.

Yet something was happening here, something far more satisfying than making money. David Buckley and Sandy Hadden were saving 4,000 barrels of oil each year—not much compared to the millions our nation consumed annually, yet it was something.

And it showed me that if each one of us did what we could, we might—just might—help heal our earth, so that it will once again become what it was when “God saw everything that he had made, and behold, it was very good.”

After arriving back home and greeting my wife, I said, “Honey, about that brick in the toilet tank…”

“No worry,” she said in a conciliatory tone, “I used it in the garden.”

“Well,” I said sheepishly, slipping my arm around her waist, “let’s put a water-filled plastic bleach bottle in there instead. I read in the paper that it will save a gallon a flush.”